Continuous Liner

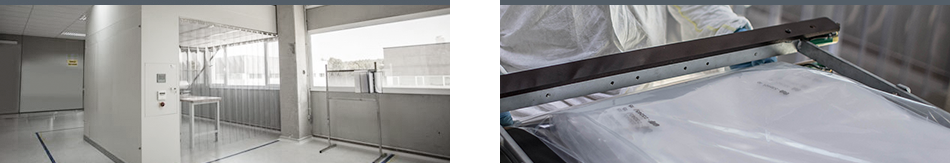

The continuous folding liner units are used in filling systems for small containers (KB-EF) and ProClean protective liner discharge systems.

The following sizes are available:

| Liner unit type 10C: | Height of liner package | 250mm |

| Liner diameter: | 315mm | |

| Length of liner | 25m | |

| Liner unit type 2C: | Height of liner package | 400mm |

| Liner diameter: | 445mm | |

| Length of liner | 50m | |

| Liner unit type 20C: | Height of liner package | 250mm |

| Liner diameter: | 445mm | |

| Length of liner | 30m | |

| Liner unit type 3C: | Height of liner package | 400mm |

| Liner diameter: | 509mm | |

| Length of liner | 50m | |

| Liner unit type 30C: | Height of liner package | 250mm |

| Liner diameter: | 509mm | |

| Length of liner | 30m | |

| Liner unit type 5C: | Height of liner package | 400mm |

| Liner diameter: | 580mm | |

| Length of liner | 50m | |

| Liner unit type 50C: | Height of liner package | 250mm |

| Liner diameter: | 580mm | |

| Length of liner | 30m |

** We can adapt our process to any size, please ask.

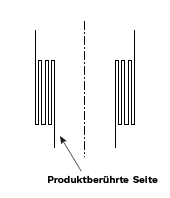

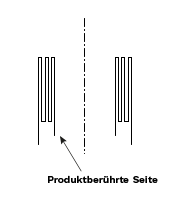

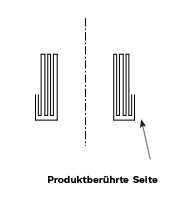

System / forms

Form A

FORM B

FORM C

FORM D

Statement on the compliance of continuous liner unit

PRODUCT DESCRIPTION:

Antistatic low density polyethylene, homopolymer stabilized with slip agent. Ethylene monomer is the only monomer used for producing the macromolecular product. For producing the above-mentioned grade there are not used plasticizers or colored master batches. The product has natural color.

PRODUCTION:

Film extrusion with subsequent folding liner finishing.

- Extrusion condition: WITHOUT OIL, controlled extrusion air, low germ and low particle.

- Finishing condition: CLEAN ROOM CLASS 5, DIN EN ISO 14644-1

- Steryle conditions: As per customer requirements (Gamma irradiation).

Properties

| TYPICAL PROPERTIES | METHOD | VALUE | UNIT |

|---|---|---|---|

| PHISICAL | |||

| Density | ISO 1183 | 0.924 | g/cm³ |

| Melt flow rate (MFR)(190°C/2.16kg) | ISO 1183 | 0.75 | g/10 min |

| MECHANICAL | |||

| Dart drop impact (100µm, Blown Film) | ASTM D 1709 | >150 | g |

| Tensile Modulus | ISO 527-1, -2 | >260 | MPa |

| Tensile Stress at Yield | ISO 527-1, -2 | >11.0 | MPa |

| Tensile Strength | ISO 527-1, -3 | ||

| >300 | % | ||

| Note: MD | |||

| >600 | % | ||

| Note: TD | |||

| THERMAL | |||

| Vicat softening temperature (A50 (50°C/h 10N)) | ISO 306 | 96.0 | °C |

| Melting Temperature | ISO 3146 | 111 | °C |

| OPTICAL | |||

| Haze (100µm) | ASTM D 1003 | <9 | °C |

| Gloss | ASTM D 2457 | ||

| (20°, 100µm) | >40 | ||

| (60°, 100µm) | >90 | ||

| FILM | |||

| Melt Temperature | 170 to 220 | °C |

Additional Properties

Natural Silica, ISO 3451-1: 0.09%

Erucamide, DIN 51451: 0.05%

Failure Energy, DIN 53373, 50µm: 5.5 J/mm

Coefficient of Friction, ISO 8295: (20%)

Water vapour permeability [g/m2*d*bar] : ≈1.25 (aprox. value)

O2 permeability [cm3/m2*d*bar]: ≈ 2150 (aprox. value)

N2 permeability [cm3/m2*d*bar]: ≈450 (aprox. value)

CO2 permeabilty [cm3/m2*d*bar]: ≈10.000 (literature value)

Surface resístanse [Ohms*m]: ≈1*1012 (23ºC / 30% relative humidity)

Service temperature range [ºC]: -20ºC to 75

Storage:24 months – if stored at 5-30ºC, rel.

Humidity 40-70%, storage in a dry and lightproof area

Approvals:

FDA 21 CFR 177.1520

1935/2004/EC

EU regulation 10/2011/EC

BSE/TSE absence

Food allergens absence according EU Directive 2007/68/EC

Heavy metal concentration (100ppm according EU Directive 94/62/EC)

ELV Directive 2000/53/EC

Phtalates and Bisphenol A absence

GMO / GVO absence

Additional informations:

The product compounds are listed in and are in conformity with Directive 2002/72/EC and Government Resolution HG 879/2005.

SLIP AGENT: Type Erucamide, is FDA approved. Our supplier has registered the product and guarantees this.

- “Erucamide (erucyl amide, amide of erucic acid) is listed in 21 CFR (FDA) in section:

- § 175.105 (adhesives).

- § 175.320 (resinous and polymeric coatings for polyolefin films) (b)(3)(iii) as amides (unsubstituted) of fatty acids from vegetable or animal oils“ for the use as an adjuvant.

- § 176.180 (components of paper and paperboard in contact with dry food.

- § 177.1200 (cellophane).

- § 177.1210 (closures with sealing gaskets for food containers), to be used in amounts of up to 5 % of the gasket composition.

- § 177.1350 (ethylene-vinyl acetate copolymers)

- § 177.1400 (hydroxyethyl cellulose film, water-insoluble), (b)(4) substances identified in and used in compliance with § 177.1200(c).

- § 177.1520 (olefin polymers), (b) referring to an adjuvant permitted by applicable regulations in §§ 170 through 189.

- § 178.3860 (release agents).

- § 179.45 (packaging materials for use during irradiation of pre-packaged foods) (d) (2) (i) as an adjuvant, in levels not to exceed 1% w/w of the polymer.

In general, these CFR sections should always be consulted for the complete context before any conclusion is made as to the allowed regulated use.”

- Quality control: Control is performed on lots.

- During test operation, the product must comply all the parameters depicted in this standard specification.

- In case of litigation, the control of the quality will be done in the presence of the client representative, using the samples kept for those cases. The samples will be taken in accordance with the sampling procedure.

-

Safety:

Low-density polyethylene is an inert commercial polymer and under normal handling induces no hazard. Product storage must be in accordance with MSDS procedure. The working people should avoid skin or eyes contact with molten polymer. As a minimal precaution to prevent eyes injury, safety glasses are indicated.

Fabrication areas should be well ventilated. Workplace environments should be kept clean and free of dust.

- Fire hazard:

Low-density polyethylene is a combustible substance, but under normal storage conditions there is no ignition hazard. In contact with flame it becomes soft, flows, ignites and burns with a light flame until exhausting. Therefore it has to be handled and stored avoiding contacts with open flames or other ignition sources. While burning, it releases high heat and a dense black smoke. In closed areas, fire fighters must use self-contained breathing apparatus.

- Recycling:

Low-density polyethylene is a recyclable material. It is recommended to recycle production rejects and wastes instead of disposal.

- Disposal:

Disposal of any wastes should respect all national and local valid regulations. The below information are related to Low density polyethylene homopolymer. The influence of the additives, fillers or other materials added by buyers must be taken into consideration using the related documentation. Low-density polyethylene homopolymer can be disposed by burying or by controlled incineration, respecting valid regulations regarding gaseous emission or solid particles discharges. Due to the high level of heat enduced, incineration has to be done only in dedicated units. In case of interring: low density polyethylene is inert, does not degrade quickly, form a strong and permanent soil base and does not release gases or other compounds known to pollute water resources.

- Country of Origin:

We hereby certify that LDPE Standard Liner Unit, is produced in EUROPE

Specific Migration Limits

We, General de Manipulados Plásticos SA, based in Castellar del Vallès 08211, Barcelona-Spain, confirm that the LDPE Standard Liner Unit homopolymer products contain authorized monomers (ethylene) and additives in accordance with the requirements of Commission Directive 2002/72/EC amended by Directive 2007/19/EC, Directive 2008/39/EC and Directive 2009/975/EC, relating to plastic materials and articles intended to come into contact with food.

These products contain additives with Specific Migration Limits (SML), or other restrictions as follows:

- LDPE products – erucamide slip additive with no SML (erucamide-no SML: 2002/72/EC Ref.No.52720).